The fuselage of the next generation of large passenger aircrafts will certainly rely on the benefits of thermoplastic composites. Greater toughness, recycling potential and faster production cycles enable the capacity to meet future aviation sector challenges.

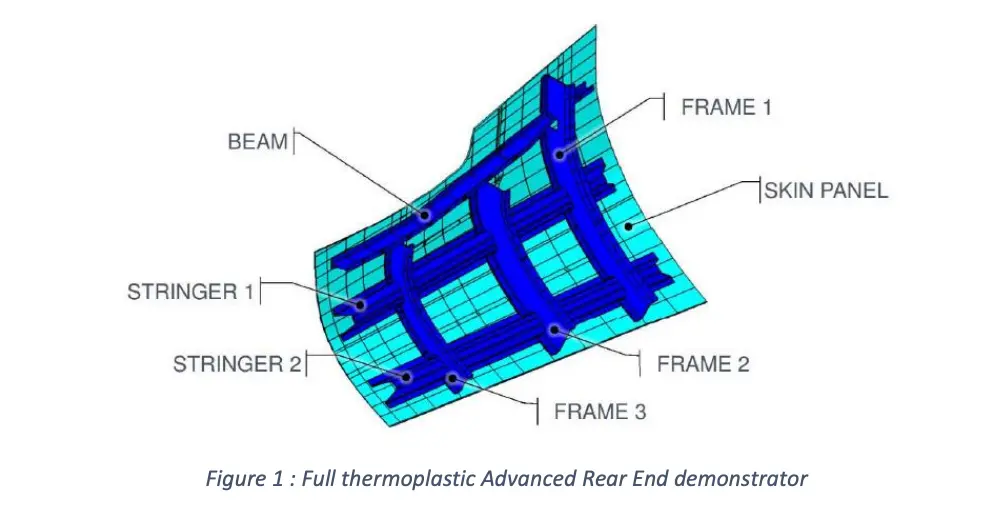

FRAMES main objective is to validate and assess a manufacturing approach of an integral thermoplastic rear end with critical design features. Key technologies developed within FRAMES will be used into a mid-scale advanced rear end demonstrator manufactured by the Deutsches Zentrum für Luft- und Raumfahrt (DLR), part of a Clean Sky 2 technology platform for large passenger aircrafts.

ESTIA-Compositadour will lead the project, perform fibre placement trials and support DLR during manufacturing and delivery of rear end demonstrator. FRAMES project kick off on end of July and will publish regular updates on progress.

For more information, you can contact Guillaume Fourage g.fourageestia.fr